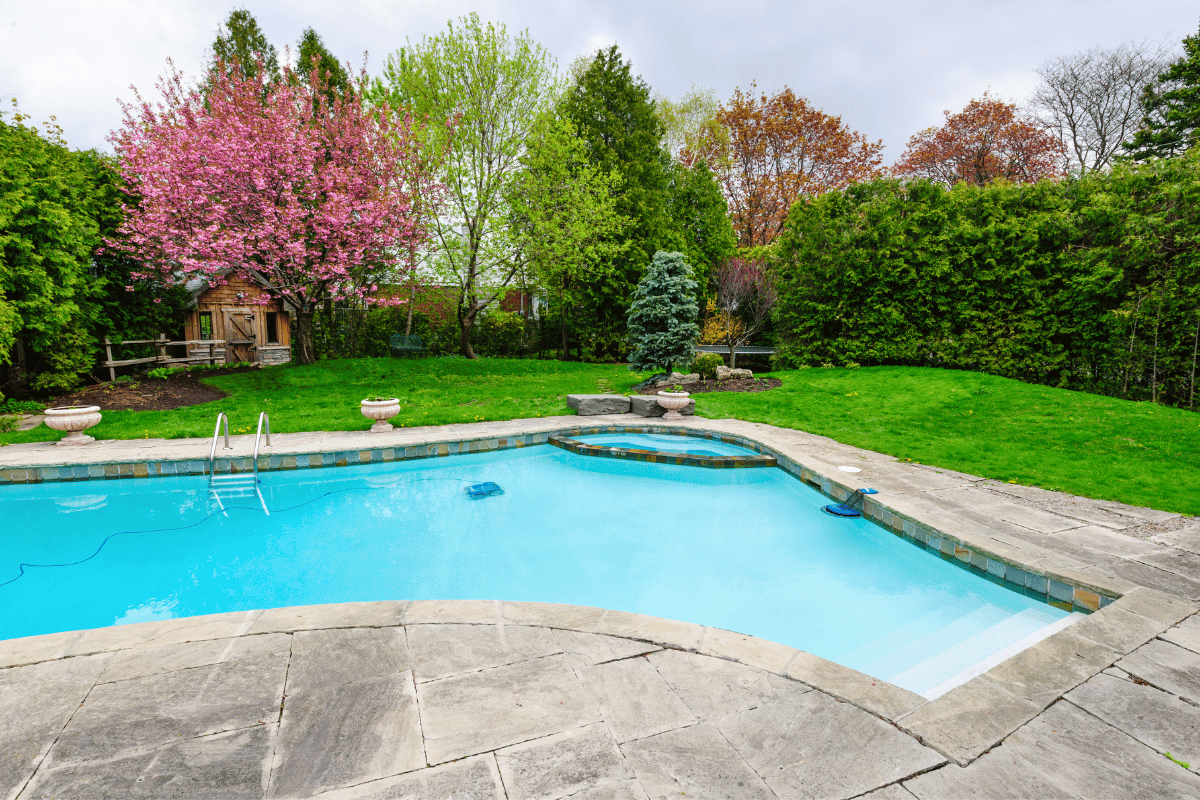

Have you ever looked at your pool deck and noticed it looking a bit… uneven? Maybe there are cracks or areas where the concrete has sunk, making it less than inviting for a sunny day dip. Well, you’re not alone! Many homeowners face this issue, and there’s a fantastic solution that’s both efficient and cost-effective: pool deck lifting.

What is Pool Deck Lifting?

Pool deck lifting is a specialized process to correct an uneven concrete deck around a swimming pool. Over time, various factors can cause sections of concrete to settle or sink, potentially creating a tripping hazard and diminishing the look of your pool area.

Why Consider Pool Deck Lifting?

Think about the last time you hosted a pool party. Was everyone having fun, or were they too busy watching their step around the uneven deck? Safety and aesthetics are two major reasons to consider lifting your pool deck. It’s about ensuring that everyone can enjoy the pool area safely and making sure your backyard looks its best.

How Does it Work?

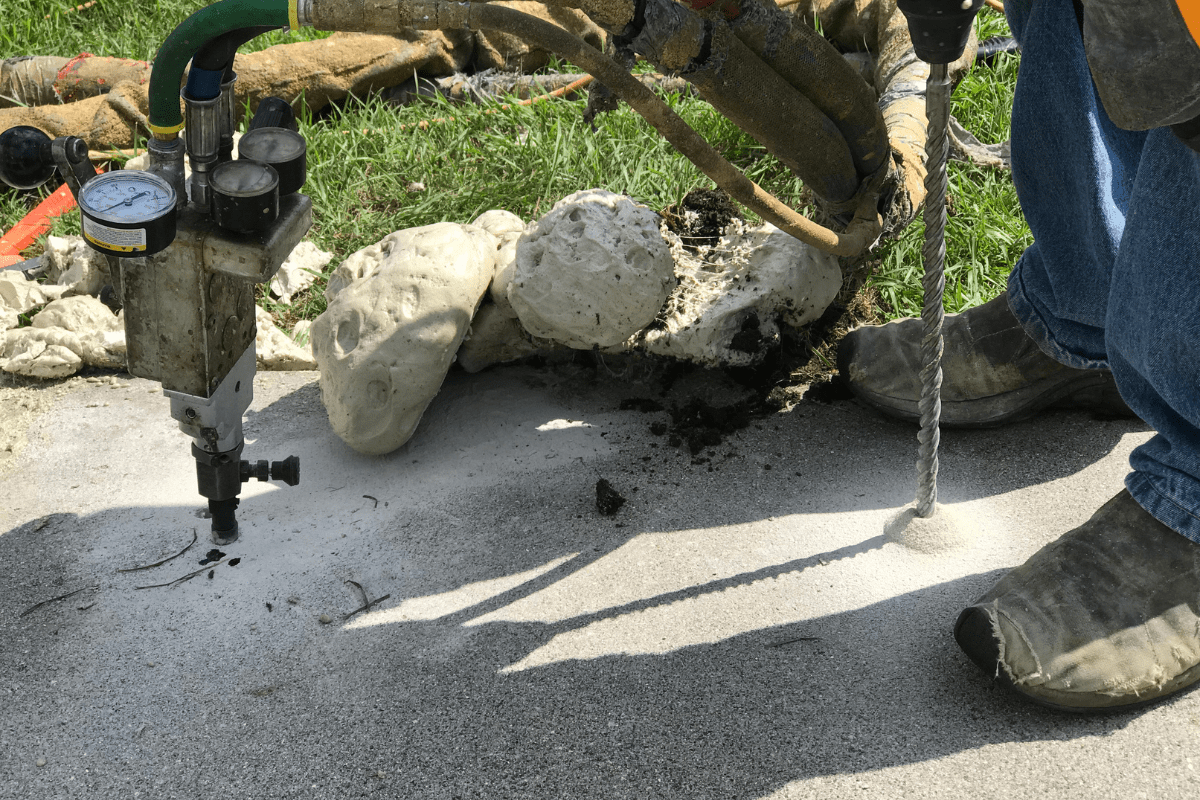

Imagine you could magically lift a cake and fix a layer that’s sunk in the middle—that’s a bit like what happens during pool deck lifting, except with concrete and a material called polyurethane foam.

Benefits

The benefits are clear: improved safety, enhanced appearance, and increased longevity of your pool area. It’s like giving your pool deck a mini facelift!

Determining the Need for Lifting

Not sure if your deck needs lifting? Signs like visible cracks or uneven surfaces are dead giveaways.

The Process

Involves drilling small holes in the concrete, injecting a foam, and watching as it lifts the concrete back to its original level.

Cost Considerations

One of the biggest advantages of pool deck lifting is cost efficiency. It’s generally less expensive than replacing the entire deck.

Preparation

Preparing your pool area for lifting is straightforward. Remove any movable objects and ensure easy access for the technicians.

Maintenance After Lifting

Maintaining your newly lifted deck involves regular inspections and ensuring proper drainage to avoid future settling.

DIY vs. Professional Services

While some may consider a DIY approach, professional services are recommended for effective and long-lasting results.

Finding the Right Contractor

Choosing the right contractor is crucial. Look for experienced professionals with positive reviews and a solid portfolio.

Common Challenges

Some challenges include finding the right time for the repair and dealing with unexpected weather changes.

The Impact on Your Home’s Value

Improving the condition of your pool deck can enhance the overall value of your home, making it a wise investment.

Conclusion

Pool deck lifting isn’t just about fixing an uneven surface—it’s about reclaiming your outdoor living space and enhancing the enjoyment and safety of your pool area. With the right approach and a skilled contractor, your pool deck can be restored to its former glory, making every poolside moment enjoyable.

Remember, your pool is more than a place to swim—it’s where memories are made. So, why wait? Consider pool deck lifting today and transform your backyard into a safe and stunning oasis.

Recent Comments