When it comes to constructing or repairing concrete slabs, ensuring stability and durability is crucial. Voids or empty spaces beneath the concrete slab can lead to various issues such as sinking, cracking, and uneven surfaces. To combat these problems, it’s essential to employ effective techniques for filling the voids. We will explore the benefits of using foam to fill voids under a concrete slab and how FoamWorks can provide reliable solutions for your needs.

What Causes Voids Under a Concrete Slab?

Before we delve into the solution, let’s understand what causes voids to form under concrete slabs. Several factors contribute to the formation of voids, including:

- Erosion: Water, over time, can wash away the soil beneath the concrete slab, creating empty spaces.

- Poor Compaction: Inadequate compaction of the soil during construction can lead to settlement and voids.

- Shifting Soil: Soil that expands and contracts due to changes in moisture content can cause voids to form.

- Plumbing Leaks: Water leakage from pipes beneath the slab can erode the soil, resulting in voids.

- Natural Factors: Environmental factors like freeze-thaw cycles, earthquakes, and subsidence can also create voids under concrete slabs.

The Risks and Consequences of Voids

Voids under a concrete slab can pose significant risks and consequences if left unaddressed. Some of the potential problems include:

- Structural Instability: Voids weaken the support beneath the slab, compromising its structural integrity.

- Uneven Surfaces: Voids can cause the slab to sink or settle unevenly, leading to tripping hazards and an unpleasant appearance.

- Cracking and Damage: Voids create stress points, increasing the likelihood of cracks and damage to the slab over time.

- Water Accumulation: Voids can allow water to accumulate, leading to moisture-related issues like mold and deterioration of the concrete.

Introducing Foam as an Effective Solution

To combat the challenges associated with voids under concrete slabs, foam has emerged as a reliable solution. Foam is a specialized material designed to fill voids and provide structural support. It is commonly used in construction projects and offers several advantages over traditional methods.

How Foam Works to Fill Voids Under a Concrete Slab

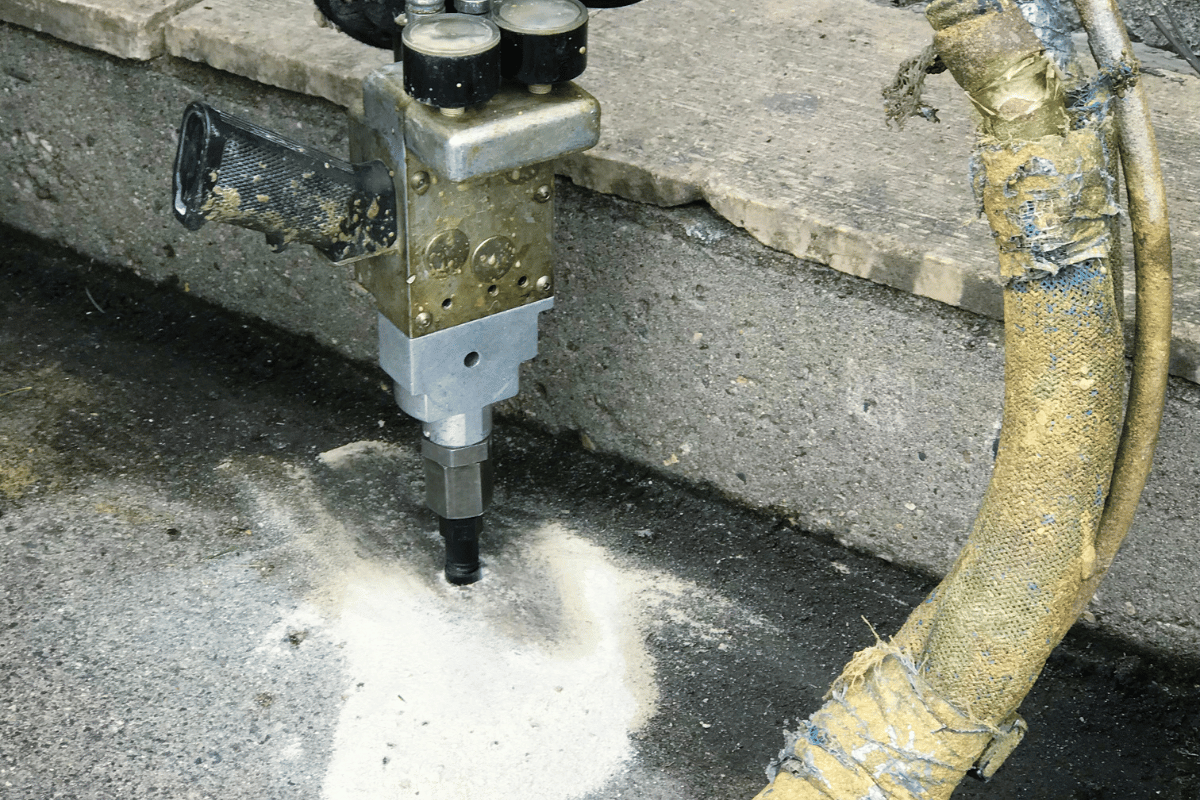

The foam used for void filling, often referred to as polyurethane foam, is a two-component system that expands upon mixing. Here’s a simplified breakdown of how foam works to fill voids under a concrete slab:

- Inspection and Preparation: Skilled professionals from FoamWorks assess the condition of the slab and identify the voids that need to be filled.

- Injection Process: Small holes are drilled into the slab, strategically placed near the voids. A specialized foam injection equipment is then used to inject the foam mixture into the voids.

- Expansion and Filling: Upon injection, the foam expands, filling the voids and exerting pressure on the surrounding soil.

- Stabilization: As the foam cures and hardens, it creates a solid support system, effectively stabilizing the slab.

- Cleanup and Finishing: After the foam has fully cured, excess foam is trimmed, and the holes are patched to restore the appearance of the slab.

Advantages of Using Foam for Void Filling

Foam offers several advantages over traditional methods when it comes to filling voids under concrete slabs. Here are some key benefits of using foam:

- Lightweight and Non-Invasive: Foam is lightweight and exerts minimal pressure on the soil, reducing the risk of further settlement or damage.

- Precision and Control: Foam injection allows for precise filling of voids, ensuring comprehensive coverage and support.

- Quick and Efficient: The foam cures rapidly, minimizing downtime and allowing for immediate use of the slab.

- Moisture Resistance: Foam is resistant to water and moisture, making it a suitable solution for void filling in areas prone to water exposure.

- Longevity and Durability: Foam provides long-lasting stability, maintaining the integrity of the slab for years to come.

- Cost-Effective: Compared to traditional methods, foam void filling is often more cost-effective due to its efficiency and reduced labor requirements.

FoamWorks: Your Trusted Partner for Void Filling Solutions

When it comes to void filling solutions, FoamWorks is the name you can trust. With years of experience in the industry, FoamWorks offers a comprehensive range of foam-related services, including void filling for concrete slabs. Here’s why you should choose FoamWorks:

- Expertise and Skill: The team at FoamWorks comprises skilled professionals who have extensive knowledge and expertise in foam applications.

- State-of-the-Art Equipment: FoamWorks utilizes advanced equipment and techniques to ensure precise and efficient void filling.

- Customized Solutions: FoamWorks understands that each project is unique, and they provide tailored solutions to meet your specific needs.

- Quality Assurance: FoamWorks is committed to delivering top-quality results, ensuring customer satisfaction and long-lasting performance.

- Timely and Reliable Service: FoamWorks values your time and strives to complete projects within agreed-upon timelines, minimizing disruptions.

Conclusion

When it comes to filling voids under a concrete slab, using foam has proven to be a highly effective and efficient solution. Foam provides stability, durability, and cost-effectiveness, offering long-term benefits for your construction projects. As a trusted provider of foam solutions, FoamWorks combines expertise, state-of-the-art equipment, and customized approaches to deliver reliable void filling services. Choose FoamWorks as your partner to use foam to fill voids under a concrete slab, and experience the difference in quality and performance.

Recent Comments