POLYURETHANE CONCRETE RAISING TECHNIQUE

Our concrete repair plan includes the controlled lift of individual slabs of concrete to realign and level the slabs. (Concrete Leveling) We achieve a precise result by applying expansive polymer foam just beneath the surface of the slab. This process eliminates the failing condition as well as seals and stabilizes all defective joints and sources of water penetration from further erosion. The variety of soils and substrates across the Front Range are often the root of the problem. Liftech’s concrete repair system treats the soils and addresses the water and erosion issues. The average life cycle of concrete is extended at a fraction of the cost of replacement.

Until recently, mudjacking has been the method more commonly used for lifting fallen concrete and is still a widely acceptable form of restoration. Mudjacking and polyurethane achieve similar results, however, the process by which those results are achieved and the extended performance of the two products are completely different.

Polyurethane Benefits

- Long-Lasting | Polyurethane cures as a solid, impermeable structure that adheres to the concrete and is not susceptible to fracture or failure.

- Soil Stabilization | Polyurethane is injected as a liquid to raise concrete and reacts within the loosely, non-compacted soils to solidify and stabilize the soils.

- Less Invasive | Liftech uses controlled injections in penny-sized holes to raise your concrete quickly and effectively

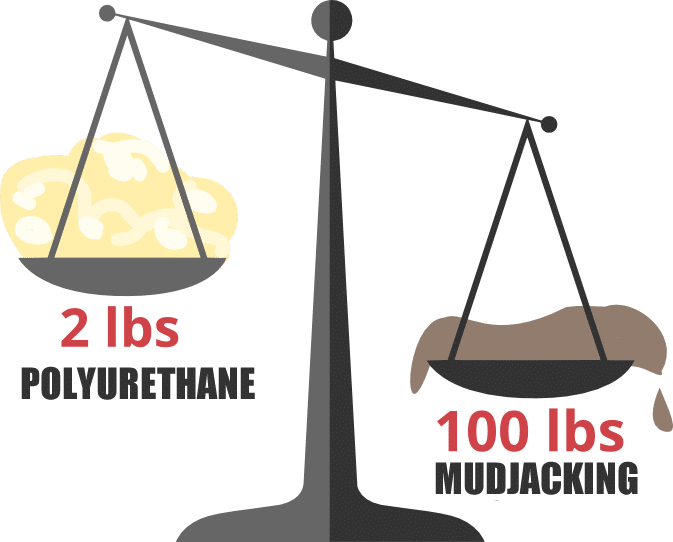

- Lightweight | Polyurethane weighs about two pounds per cubic ft. which is ideal for concrete leveling

- Fast Acting | Polyurethane cures within minutes and your concrete is ready to use again once we leave the job site.

- Defend Against Natural Erosion | Our environmentally friendly solution creates an eco-barrier to moisture, harmful chemicals, insects, rodents, and soil erosion.

WHAT IS MUDJACKING?

| Answer | Mudjacking uses a mixture of sand and water infused with a small amount of Portland cement, which helps the material solidify. The sand and water mixture is pumped through 1 – 5\8″ holes in the concrete using hydraulic pressure to lift the sunken concrete. This concrete mixture is considered a structural fill and is very heavy, weighing an average of 100 – 110 pounds per cubic foot of material.

Benefits of Polyurethane Concrete Raising Vs Mudjacking

| Answer | Polyurethane concrete raising consists of an environmentally safe liquid polymer foam that is injected through penny-size holes in the concrete and into the loose, unstable soil below. Through an eco-friendly chemical reaction, the high-density foam expands to stabilize the loose soils and lift the fallen concrete. After approximately 15 minutes, the polyurethane material is fully cured and ready to return to service. the polyurethane only weighs about 2 pounds per cubic foot of material. Polyurethane foam is an inert, non-toxic, environmentally safe material. It is impervious to moisture or decay, ensuring that over time, it will not only be environmentally friendly, but your concrete repair will last a lifetime. Liftech’s polyurethane system utilizes a much smaller, 5/8 inch hole (about the size of a penny). Following the repair, those holes are filled with chemical grouting that matches the surrounding concrete.

There are other ways to repair concrete, you can learn about them on our services page.

Recent Comments