Uneven sidewalks can be a significant problem for homeowners and businesses alike. Not only do they pose safety hazards, but they also detract from the overall appeal of a property. If you’re dealing with the frustration of an uneven sidewalk, you’ve come to the right place. With our expertise and advanced techniques, we can transform your uneven sidewalk into a smooth and sturdy pathway. Let’s explore the numerous benefits of using polyurethane foam on how to fix an uneven sidewalk and how FoamWorks can help you achieve remarkable results.

Understanding the Causes of Uneven Sidewalks

When it comes to understanding the causes of uneven sidewalks, it’s essential to delve into the underlying factors that contribute to this common problem. By identifying these causes, we can effectively address and rectify the issue. At FoamWorks, we have extensive knowledge of the following factors that often lead to uneven sidewalks:

Expansive Soil and Its Impact on Concrete Stability

One significant cause of uneven sidewalks is expansive soil. Certain types of soil, such as clay, have the tendency to expand and contract with changes in moisture content. This continuous movement can exert significant pressure on the concrete, resulting in cracks and unevenness over time.

Effects of Tree Roots, Erosion, and Heavy Loads on Sidewalk Integrity

Tree roots can be a silent culprit behind uneven sidewalks. As trees grow, their roots can infiltrate the soil beneath the sidewalk, causing it to uplift or settle unevenly. Additionally, erosion caused by water flow or heavy loads placed on the sidewalk can gradually weaken its structural integrity and lead to uneven surfaces.

Weather Conditions and Their Contribution to Sidewalk Settlement

Weather conditions play a crucial role in sidewalk settlement. Freeze-thaw cycles, common in colder regions, can cause the ground beneath the sidewalk to heave and settle unevenly. Similarly, prolonged exposure to excessive moisture, such as heavy rainfall or poor drainage, can contribute to soil instability and result in uneven sidewalks.

By understanding these causes, FoamWorks can accurately assess the extent of damage to your sidewalk and provide tailored solutions using polyurethane foam. Our expertise allows us to address the underlying issues and restore your sidewalk to its optimal condition, ensuring safety and durability for years to come.

Signs of an Uneven Sidewalk

Identifying the signs of an uneven sidewalk is crucial for prompt action and ensuring the safety and functionality of your walkway. Here are some key indicators to look out for:

Visible Cracks, Gaps, or Separations

One of the most apparent signs of an uneven sidewalk is the presence of cracks, gaps, or separations in the concrete. These visible irregularities can occur due to soil movement, root intrusion, or other underlying factors. Pay close attention to any noticeable shifts or breaks in the surface.

Trip Hazards and Safety Concerns

Uneven sidewalks often create trip hazards that can lead to accidents and injuries. If you notice raised or sunken sections of the sidewalk, it’s crucial to address them promptly. Trip hazards can pose risks not only to pedestrians but also to property owners who may be liable for any accidents that occur on their premises.

Drainage Issues and Water Pooling

Another sign of an uneven sidewalk is inadequate water drainage or pooling. If water accumulates or fails to drain properly, it may indicate an uneven surface that hinders the natural flow of water. This can result in water damage, erosion, and further deterioration of the sidewalk if left unaddressed.

Why Choose Polyurethane Foam for Sidewalk Repair

When it comes to repairing an uneven sidewalk, choosing the right method is essential for achieving long-lasting results. At FoamWorks, we specialize in utilizing polyurethane foam for sidewalk repairs, and here’s why it’s the superior choice:

Advantages of Polyurethane Foam over Traditional Repair Methods

Polyurethane foam offers several distinct advantages over traditional repair methods such as mudjacking or concrete replacement. Firstly, polyurethane foam is lightweight, allowing for precise and controlled injection into voids beneath the sidewalk. This minimizes the disruption to the surrounding area and reduces the chances of further damage. Additionally, polyurethane foam provides a more accurate and consistent lift, resulting in a level and even surface.

Environmentally-Friendly and Long-Lasting Qualities

Choosing polyurethane foam for sidewalk repair is an environmentally-friendly option. The foam is composed of non-toxic materials and does not release harmful chemicals into the environment. Furthermore, polyurethane foam has exceptional durability, providing long-lasting results. It resists moisture, prevents soil erosion, and maintains its structural integrity over time, ensuring your repaired sidewalk stands the test of time.

Cost-Effectiveness and Time Efficiency

Opting for polyurethane foam repair is not only beneficial for its quality but also for its cost-effectiveness and time efficiency. Compared to traditional methods that require extensive excavation or complete sidewalk replacement, polyurethane foam repair requires minimal disruption and significantly reduces labor and material costs. The process is efficient, allowing for quicker project completion and minimizing the inconvenience caused by prolonged construction.

How to Fix an Uneven Sidewalk with Polyurethane Foam

Are you ready to learn how to fix an uneven sidewalk and transform it into a smooth and level surface using polyurethane foam? Follow this comprehensive step-by-step guide provided by FoamWorks, and you’ll be on your way to a professionally repaired sidewalk that is safe and visually appealing.

Preparing the Workspace and Ensuring Safety

Prioritize safety by preparing the workspace. Clear the area of any obstacles or debris that may hinder the repair process. Use caution signs or barriers to alert pedestrians to the ongoing work and ensure their safety. It’s also essential to wear appropriate personal protective equipment (PPE) during the repair.

Assessing the Severity of the Sidewalk Damage

Begin by assessing the extent of the sidewalk damage. Identify areas of settlement, cracks, or voids that need repair. This evaluation will help determine the amount of polyurethane foam required for the project.

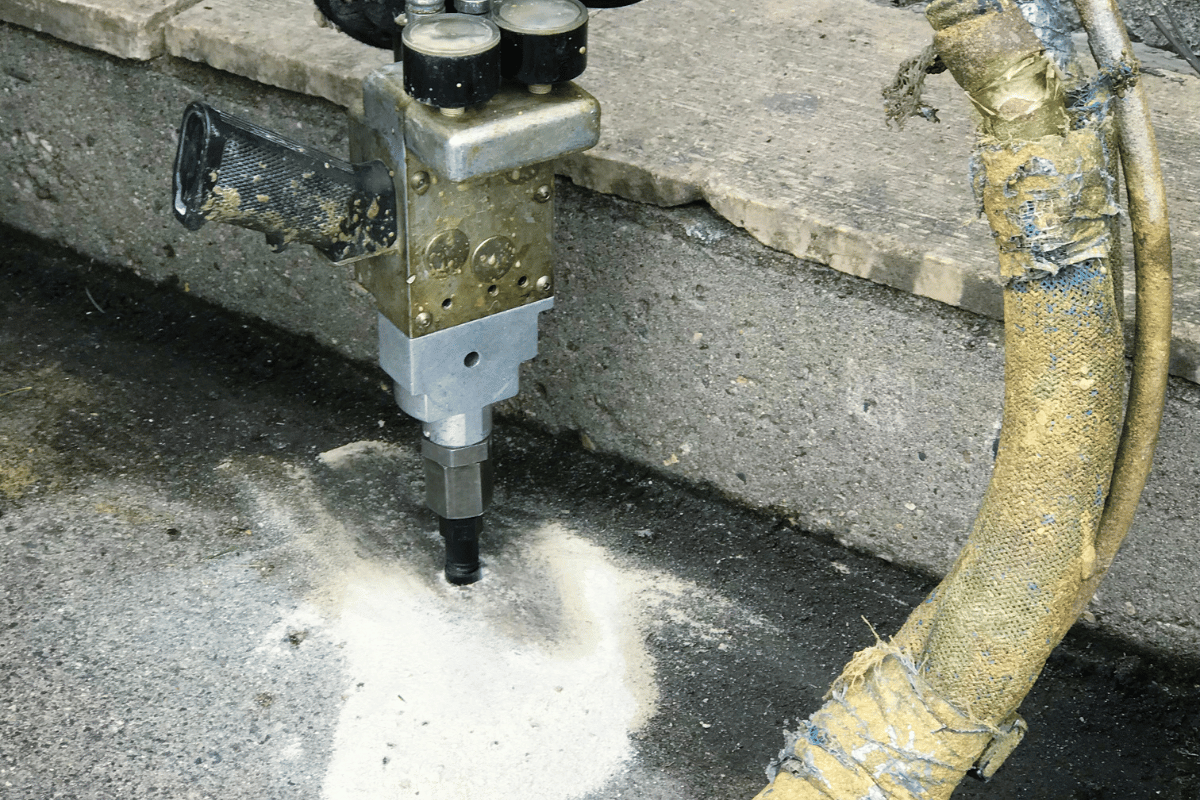

Injecting Polyurethane Foam into Voids and Stabilizing the Concrete

With the assessment complete, it’s time to inject polyurethane foam into the voids beneath the sidewalk. FoamWorks uses specialized equipment to precisely inject the foam, which expands and fills the voids, lifting and stabilizing the concrete in the process. The foam also acts as a strong foundation, preventing further settling or shifting.

Monitoring and Adjusting the Leveling Process

As the polyurethane foam expands and lifts the concrete, it’s crucial to monitor the leveling process. Our experienced technicians carefully observe the sidewalk, ensuring an even and consistent lift. If necessary, adjustments can be made to achieve the desired levelness.

Finishing Touches and Cleanup

Once the leveling process is complete, any excess foam is trimmed, and the surface is smoothed out. The repaired area is then left to cure, which typically takes a short amount of time. Finally, the work area is cleaned up, leaving your sidewalk looking rejuvenated and ready for use.

Benefits of Polyurethane Foam for Sidewalk Repair

Polyurethane foam is not only a reliable solution for fixing uneven sidewalks, but it also provides valuable insights on how to fix an uneven sidewalk while offering numerous benefits that go beyond surface-level repairs. Here are the key advantages of using polyurethane foam for your sidewalk repair needs:

AImproved Structural Integrity and Durability

Polyurethane foam provides excellent structural support and stability to your sidewalk. Once injected, the foam expands, filling voids and stabilizing the concrete, effectively addressing the underlying issues that caused the unevenness. This results in a strong and durable sidewalk that can withstand heavy foot traffic, weather conditions, and other external factors for years to come.

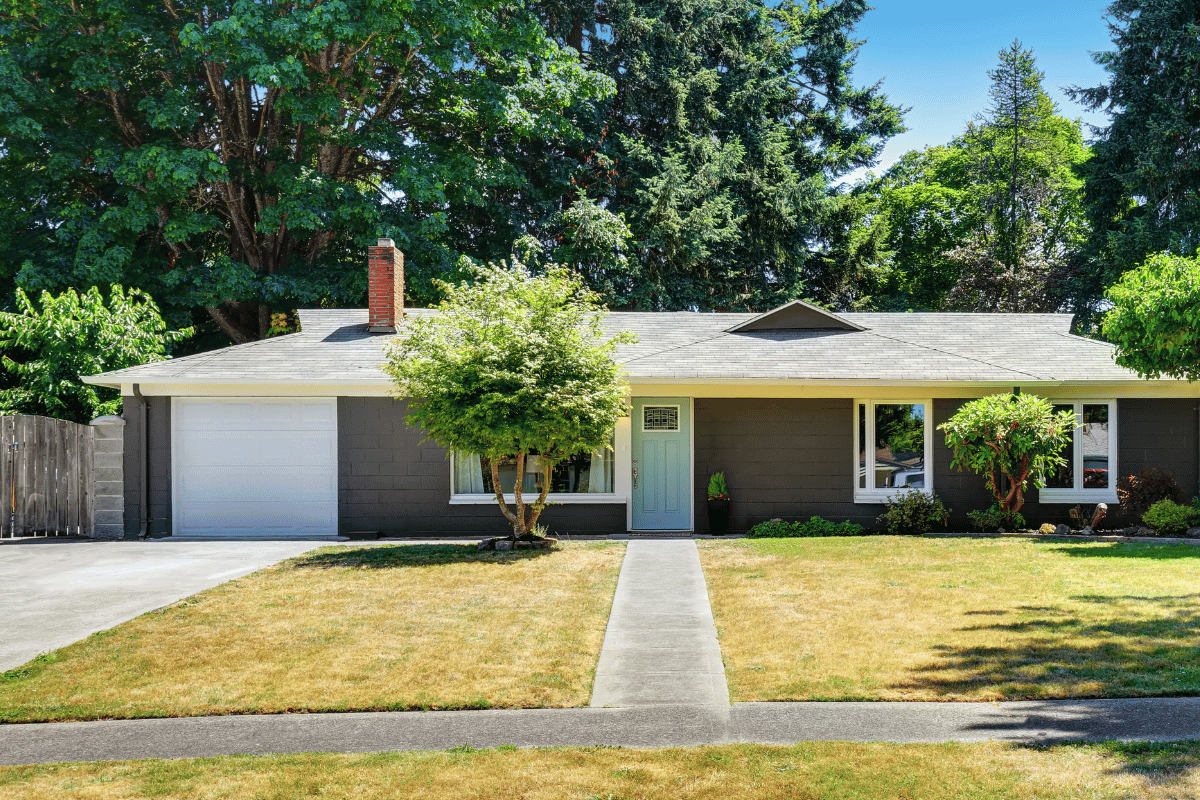

Enhanced Aesthetics and Curb Appeal

Repairing your uneven sidewalk with polyurethane foam not only restores its functionality but also improves its appearance. The foam lifts and levels the concrete, eliminating cracks, gaps, and uneven surfaces. This creates a smooth and visually appealing sidewalk that enhances the curb appeal of your property, making it more attractive to visitors and potential buyers.

Minimized Future Maintenance and Repair Needs

By using polyurethane foam for your sidewalk repair, you can significantly reduce the likelihood of future maintenance and repair requirements. The foam acts as a long-term solution, providing a stable foundation that resists settling, soil erosion, and other common issues. This minimizes the need for frequent repairs and costly maintenance, saving you time and money in the long run.

Conclusion

In conclusion, when it comes to repairing uneven sidewalks, polyurethane foam emerges as the ideal solution for its numerous benefits and effectiveness in addressing the problem. By choosing polyurethane foam for your sidewalk repair needs, you can learn how to fix an uneven sidewalk and experience improved structural integrity, enhanced aesthetics, and minimized future maintenance requirements. With its ability to stabilize and lift concrete, polyurethane foam provides a durable and long-lasting solution that enhances the overall appeal of your property.

At FoamWorks, we specialize in delivering exceptional results using polyurethane foam. Our team of experts is equipped with the knowledge, skills, and advanced techniques to transform your uneven sidewalk into a safe and attractive pathway. By trusting us with your sidewalk repair project, you can have peace of mind knowing that you are receiving professional assistance from a reliable concrete repair company.

Maintaining safe and attractive sidewalks is of utmost importance for homeowners and businesses alike. A well-maintained sidewalk not only ensures the safety of pedestrians but also adds value to your property. Don’t let uneven sidewalks be a persistent issue. Contact FoamWorks today to schedule a consultation and allow our experienced team to provide the high-quality repairs your sidewalk deserves.

Remember, a level and smooth sidewalk is more than just a functional path – it reflects the pride you have in your property. Let FoamWorks help you revitalize your sidewalk and create a safer, more appealing environment. Reach out to us today and take the first step towards achieving a beautiful and well-maintained sidewalk that stands the test of time.

Recent Comments