If you’ve ever wondered why foam is used in concrete slabs, you’re not alone. This innovative method has become increasingly popular in the construction and repair of concrete surfaces, and for good reason. Let’s explore the benefits and applications of foam in concrete slabs, and why it’s a game-changer for homeowners and professionals alike.

What is Foam Injection?

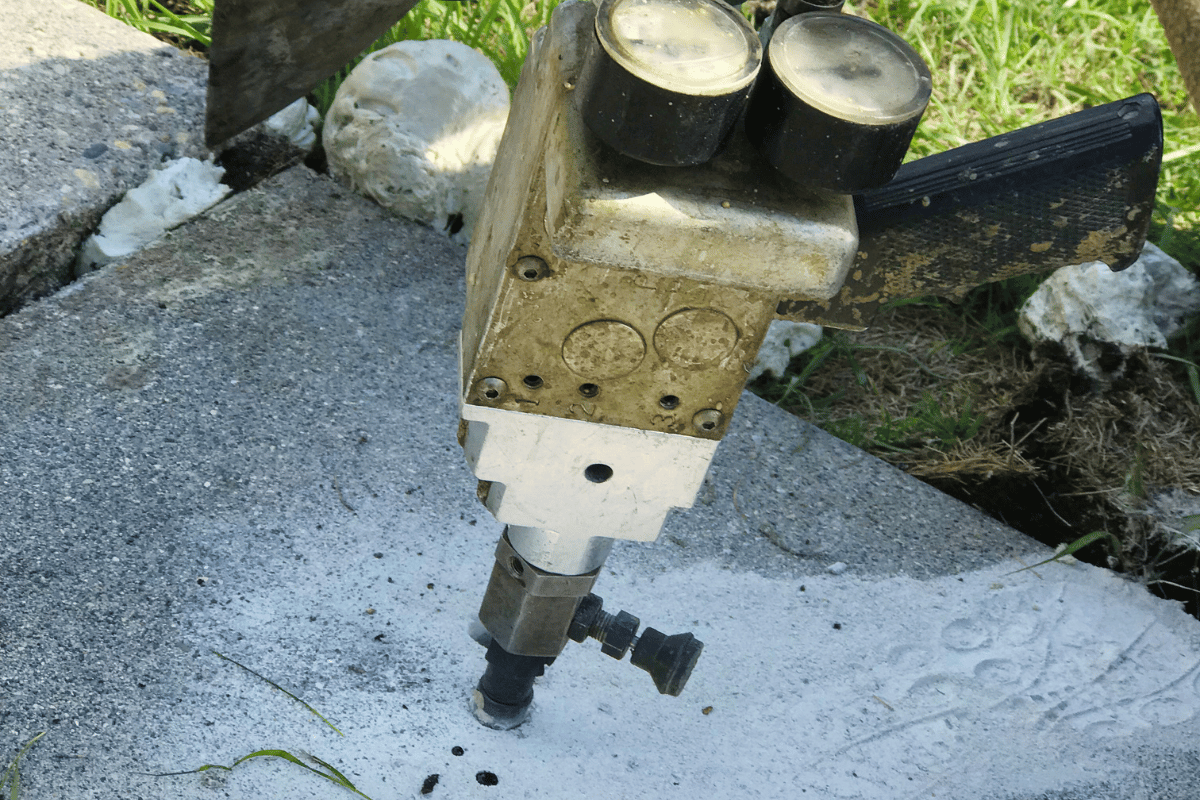

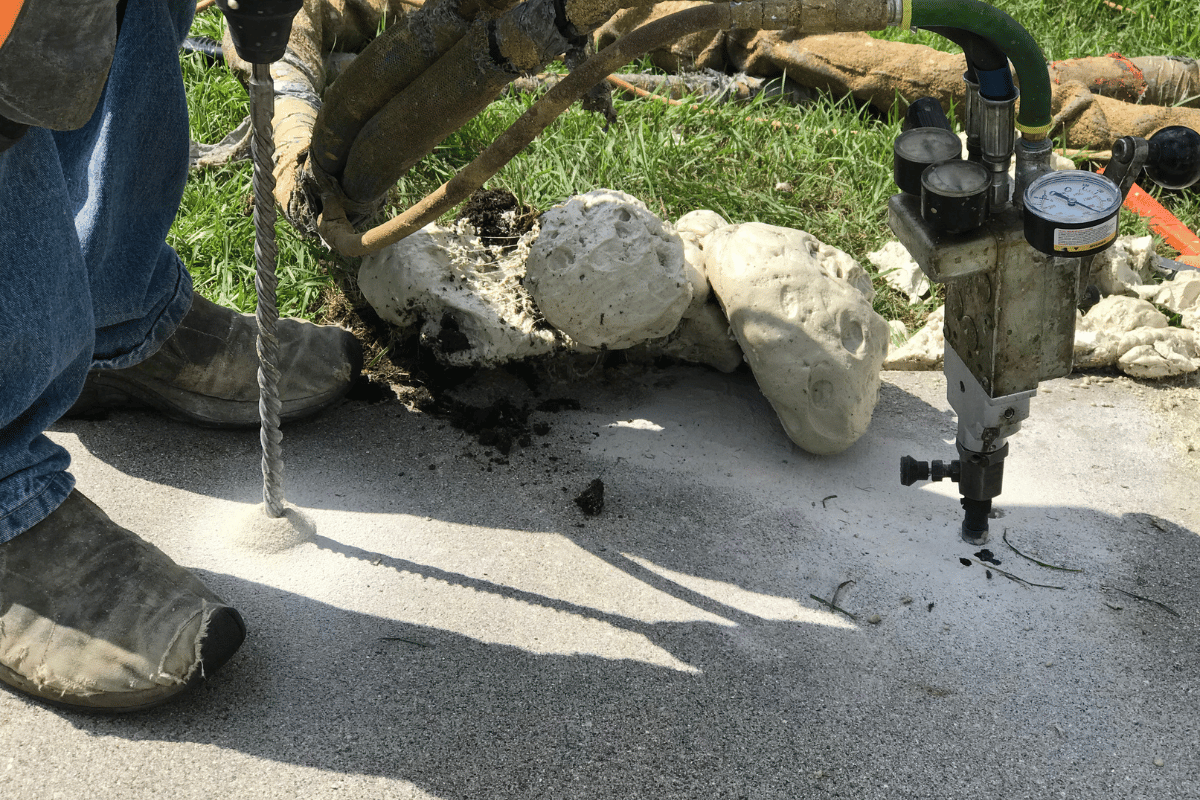

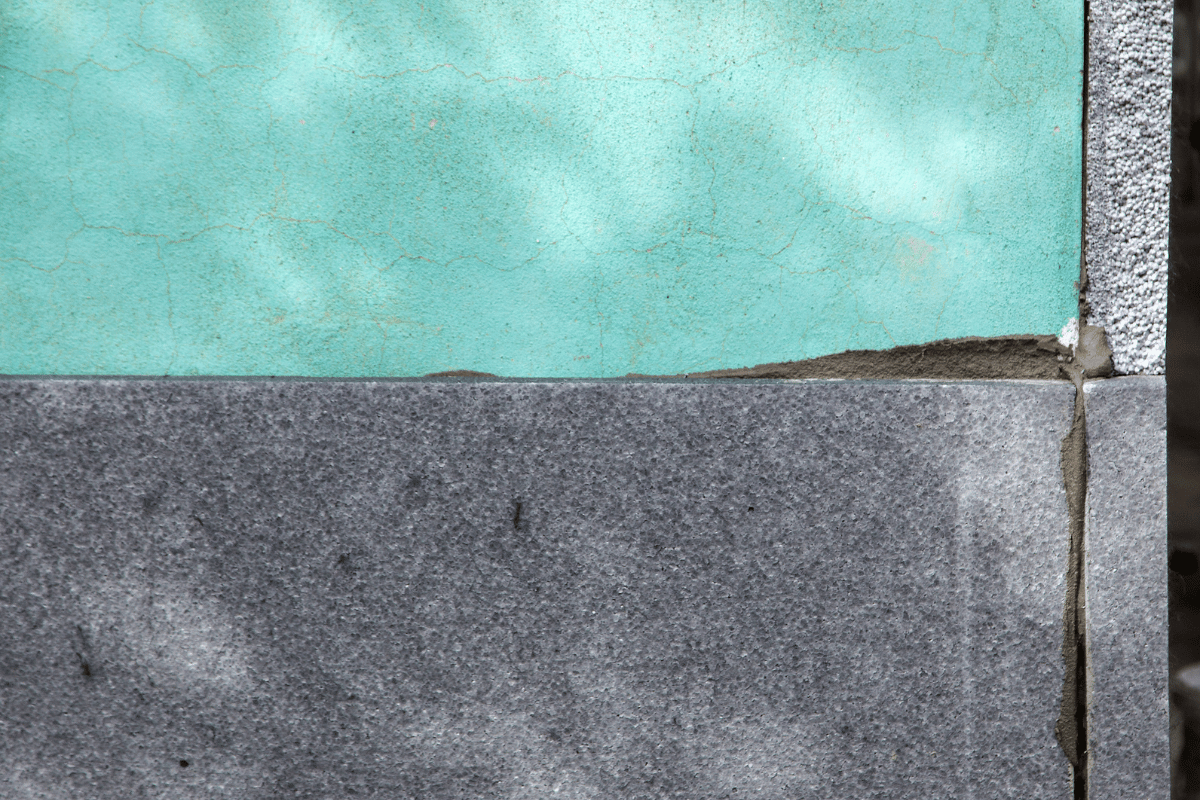

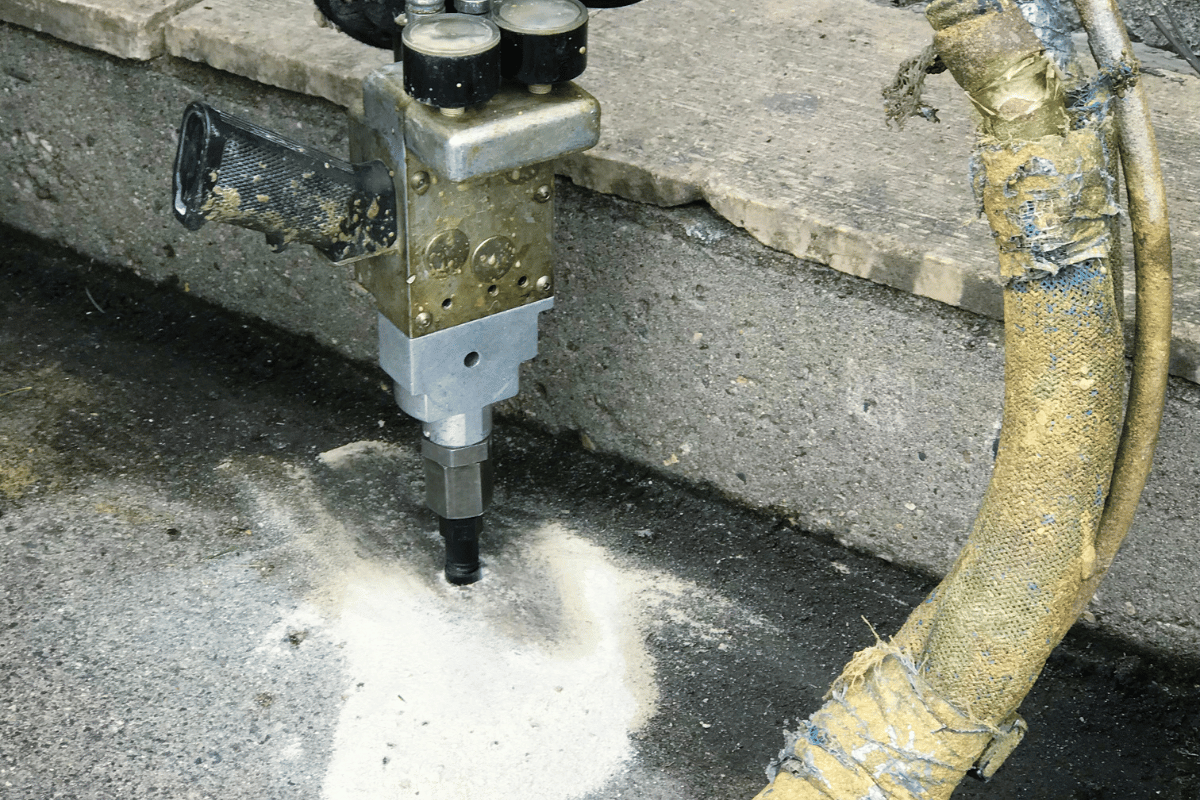

Foam injection, also known as polyurethane foam injection, is a technique used to lift, level, and stabilize concrete slabs. It involves injecting a high-density foam beneath the concrete surface, which expands and hardens, filling voids and raising the slab to its original position. This method is commonly used for repairing driveways, patios, sidewalks, and other concrete surfaces that have become uneven over time.

The Benefits of Foam in Concrete Slabs

- Quick and Efficient: One of the main reasons foam is used in concrete slabs is its speed and efficiency. Traditional methods of concrete repair can be time-consuming and labor-intensive. Foam injection, on the other hand, can be completed in a matter of hours, with minimal disruption to your daily routine.

- Cost-Effective: Foam injection is a cost-effective solution compared to full slab replacement. It requires fewer materials and less labor, which translates to lower costs for homeowners and businesses. Additionally, the quick turnaround time means less downtime and inconvenience.

- Durable and Long-Lasting: The high-density foam used in this process is extremely durable and resistant to moisture, chemicals, and pests. Once the foam hardens, it provides strong, long-lasting support to the concrete slab, ensuring that it remains level and stable for years to come.

- Minimal Disruption: Foam injection is a non-invasive process that causes minimal disruption to the surrounding area. There’s no need for heavy machinery or extensive excavation, making it an ideal solution for residential and commercial properties.

- Environmentally Friendly: Many foam products used in concrete repair are environmentally friendly and made from recycled materials. This makes foam injection a sustainable choice for those looking to reduce their environmental impact.

Applications of Foam in Concrete Slabs

Foam injection is versatile and can be used in a variety of applications, including:

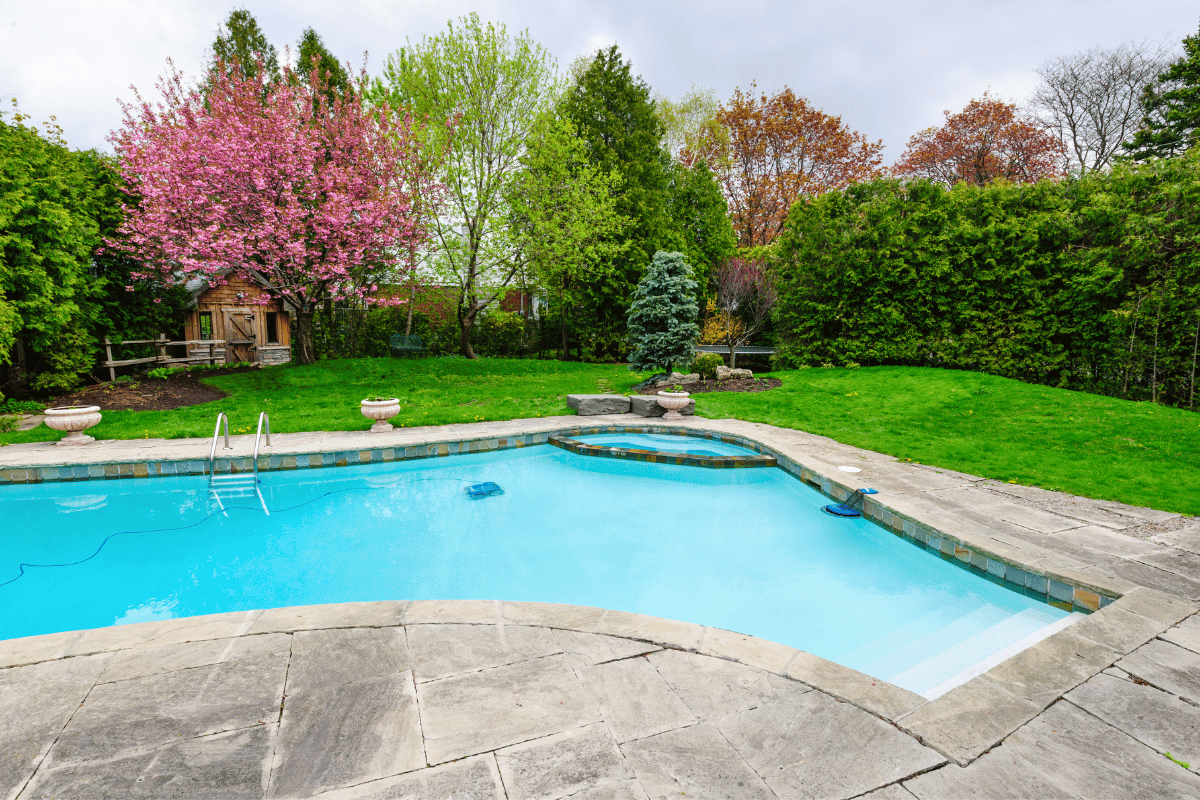

- Driveways: Uneven driveways can be a safety hazard and an eyesore. Foam injection quickly levels the surface, making it safe and visually appealing.

- Patios and Sidewalks: Over time, patios and sidewalks can sink and become uneven due to soil erosion and settling. Foam injection restores these surfaces to their original state.

- Basement Floors: In homes with basement floors that have settled or become uneven, foam injection provides a quick and effective solution to level the surface.

- Garage Floors: Uneven garage floors can cause damage to vehicles and create trip hazards. Foam injection ensures a smooth, level surface that is safe and functional.

Why Choose FoamWorks?

At FoamWorks, we specialize in foam injection for concrete slab repair. Our experienced team uses the latest techniques and high-quality materials to ensure your concrete surfaces are level, stable, and durable. Whether you’re dealing with a sunken driveway or an uneven patio, we have the expertise to get the job done right.

Foam injection is a modern, efficient, and cost-effective solution for repairing and stabilizing concrete slabs. Its numerous benefits make it the preferred choice for homeowners and professionals looking to address uneven concrete surfaces. If you’re ready to restore your concrete to its original condition, contact FoamWorks today to learn more about our foam injection services!

Recent Comments