It’s no secret that parking lots can often become uneven and bumpy over time. This can not only be unsightly, but it can also pose a safety hazard for both drivers and pedestrians. Luckily, there is a solution – parking lot leveling.

Leveling your parking lot can help to improve its overall appearance and make it safer for everyone who uses it. In this blog post, we’ll take a look at what causes parking lots to become uneven, the benefits of leveling them, and how the process works. We hope you find this information helpful!

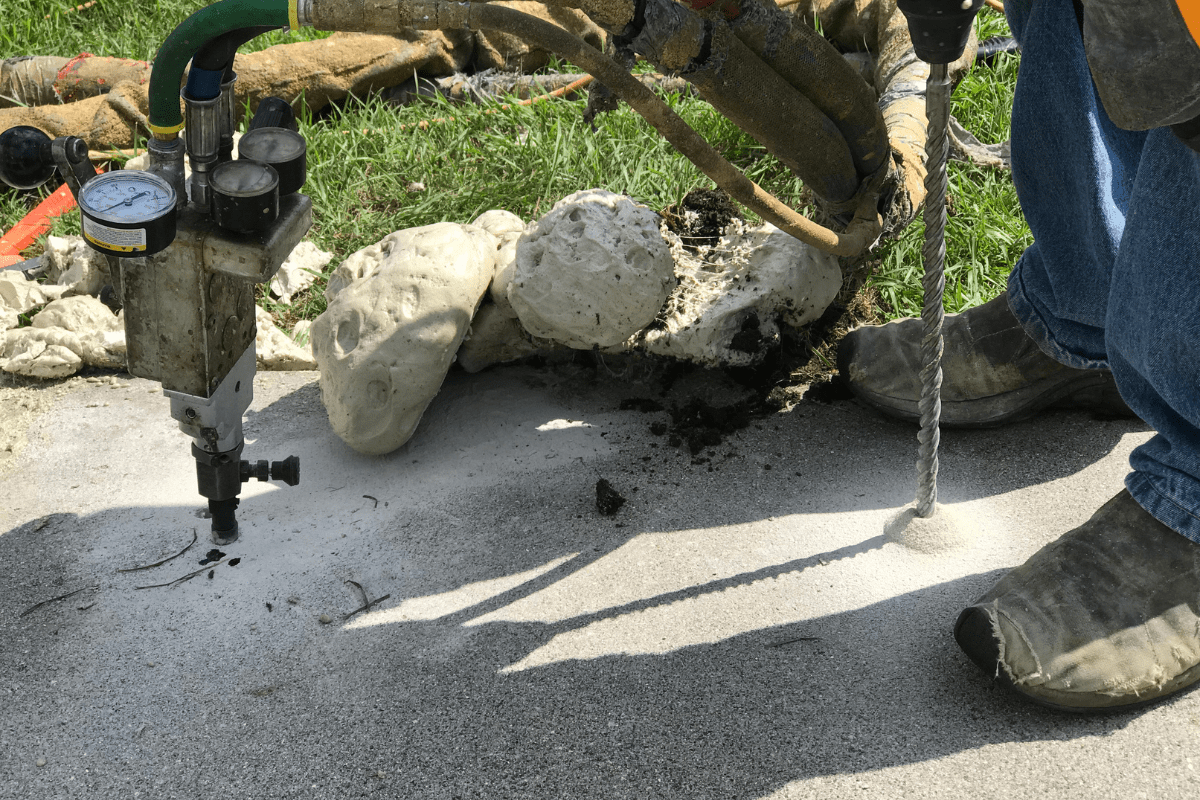

The Process of Parking Lot Leveling

Parking lot leveling is a necessary process for creating a safe and level parking lot that can withstand the weight of parking lot traffic. In order to make sure an even surface is achieved, parking lot leveling often consists of several different steps, such as excavating existing parking lots and re-grading them to create new slopes and fill any holes. The next step involves installing drainage systems to ensure water runs off in the right way. After this is done, a layer of crushed gravel may be added before adding asphalt. This final phase helps smooth out the parking lot while ensuring there are no holes or low points. Proper parking lot leveling is crucial for providing customers with a safe and level parking experience each time they visit.

Why it’s Important to Have a Level Parking Lot

Having a level parking lot is incredibly important. It prevents vehicles from scraping or bottoming out when they enter or leave the parking lot, which reduces the upkeep of the lot and saves money in the long run. Level lots provide increased safety for people because it makes getting into and out of vehicles easier, lessening the probability of falls and other injuries. In addition, level lots are visually appealing, conveying a level of professionalism that customers appreciate. To ensure optimal levelness, businesses should pay close attention to their parking surface regularly and take any necessary corrective actions when needed. Taking these proactive steps will go a long way in maintaining a safe and professional level parking lot for everyone to enjoy.

How to Tell if your Parking Lot Needs to be Leveled

Leveling a parking lot can be an important investment for business owners who want to create curb appeal and customer satisfaction. In order to tell if your parking lot needs to be leveled, look out for cracks in the pavement and areas of pooling water. Erosion from rainwater can lead to cracked asphalt, which can become increasingly hazardous over time as pieces of the pavement chip off and become a safety hazard. If you see any potholes or large cracks in your pavement, it might be time to invest in leveling. Additionally, look out for water pooling on the surface of the pavement – if water saturates the asphalt instead of draining away, then this is a sign that your lot has started sinking and requires grading and leveling.

The Benefits of Having a Level Parking Lot

Having a level parking lot is an important part of running a successful business. Not only does a flat, level parking lot make it easy to navigate and park vehicles, but by preventing potholes and other common defects in a parking area, it also contributes to the safety of drivers. Furthermore, an even surface prevents drainage problems and keeps water from pooling around parked cars. Additionally, businesses can benefit from presenting customers with an appealing, professional-looking entrance with a properly-maintained level asphalt or concrete parking lot. Customers will feel welcome at any establishment that takes the time and effort to provide them with this convenience. Level parking lots are also easier to clean and require fewer areas for repairs than slanted or uneven ones, making them cost effective in the long run.

When to Call in a Professional for Help

When parking lots experience wear and tear or severe weather damage, it is important to recognize the need for professional help. Attempting to repair parking lots with DIY tips may seem easier from a financial perspective but can lead to costly problems later on. As an experienced parking lot repair specialist, we will be able to identify existing and potential drainage woes such as cracks, unevenness of paving, and fissures in parking spaces. Professionals like us will also have the right tools and skillset to make parking lot repairs quickly and accurately for your business or property’s long-term benefit.

Parking lot leveling is an important process to maintain the safety and usability of your parking lot. At FoamWorks, we specialize in parking lot repair and can help you get your lot back into shape. Contact us today for a free consultation!

Recent Comments