Tired of tripping over uneven sidewalks that spoil your home’s curb appeal? Raising sidewalks with foam might just be the solution you need! Whether it’s soil settling, weather shifts, or initial poor installation, sunken sidewalks can pose real safety risks. Let’s dive into how to raise sidewalks with foam and discover why it’s a superior choice compared to traditional methods.

Why Sidewalks Sink

Sidewalks can sink due to a variety of reasons, including soil settling, erosion, or invasive tree roots. Traditional repair methods like mudjacking or completely replacing the slab can be messy, take ages, and hit your wallet hard. Luckily, there’s a better way—raising sidewalks with foam. This method is cleaner, quicker, and offers a more lasting solution, all while keeping your property disruption to a minimum.

What is Foam Lifting?

Foam lifting, also known as polyurethane foam injection, involves pumping high-density foam right under your concrete slab. As the foam expands, it fills the gaps and gently elevates the concrete back to where it belongs. This method is quickly becoming a favorite for its efficiency and long-lasting results.

How to Raise Sidewalk with Foam: The Step-by-Step Process

- Assessment: First, we take a good look at the area to pinpoint the best spots for injection. Our skilled team assesses the damage and figures out where the foam needs to go to do its magic.

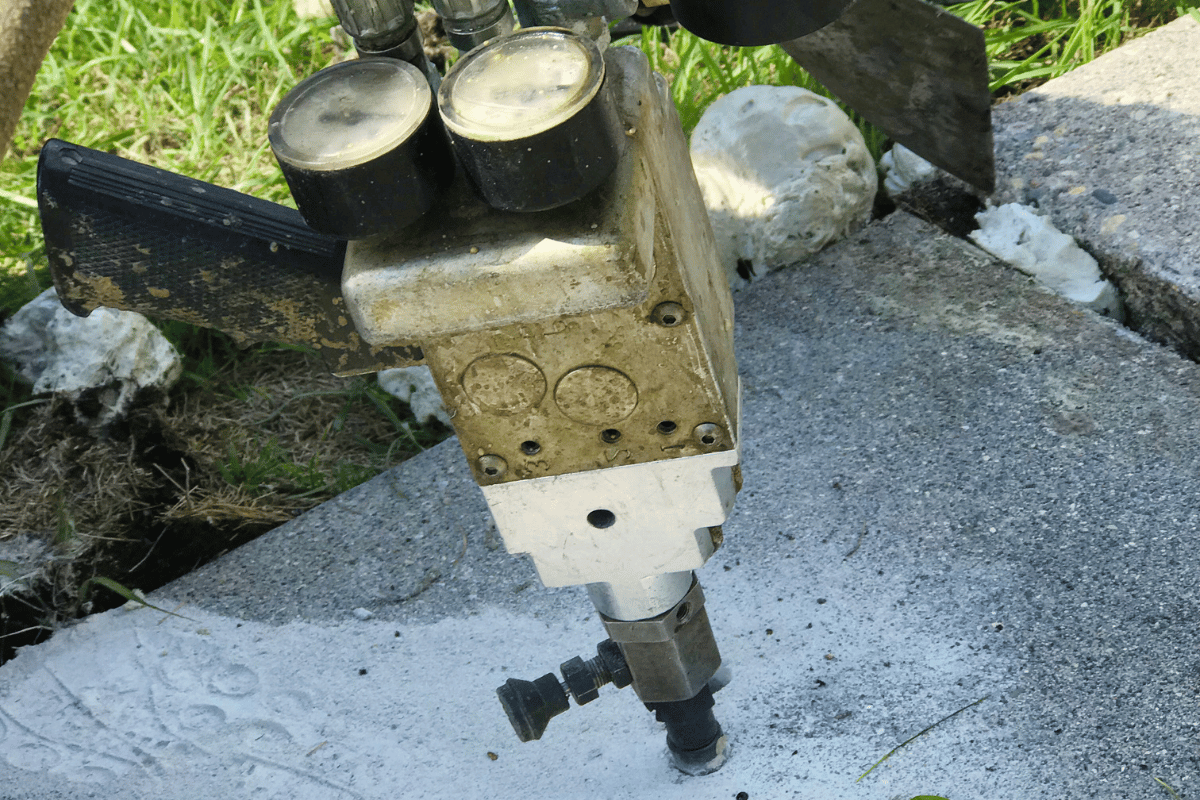

- Drilling: We drill small, discreet holes into the concrete slab. These holes are much smaller than those used in traditional mudjacking, which makes the whole process less invasive and helps keep your sidewalk looking great.

- Foam Injection: High-density polyurethane foam is injected through the drilled holes. The foam expands quickly, filling the voids beneath the concrete and lifting the slab back into place. This process usually takes only a few minutes per injection point.

- Cleanup: Once the foam has fully expanded and the sidewalk is leveled, the holes are patched up, and the site is cleaned. The result is a smooth, level sidewalk without the need for heavy equipment or prolonged wait times.

- Ready to Use: One of the biggest advantages of raising sidewalks with foam is the quick curing time. Unlike traditional methods that require days to set, foam lifting allows you to use your sidewalk almost immediately.

Why Choose FoamWorks for Sidewalk Lifting?

At FoamWorks, we’re experts in raising sidewalks with foam and always choose the best materials and techniques for flawless results. Our dedicated team ensures top-notch service every step of the way, from your first consultation to the final cleanup. We’re proud to offer an effective, environmentally friendly, and non-invasive solution to your sidewalk issues.

The Benefits of Raising Sidewalk with Foam

- Quick and Efficient: The entire process is usually completed within a few hours, and you can walk on your sidewalk right away.

- Cost-Effective: Foam lifting is often more affordable than replacing the entire slab, saving you both time and money.

- Long-Lasting Results: The foam is highly durable, resisting water, erosion, and extreme temperatures, providing a long-term fix for your sidewalk issues.

- Eco-Friendly: The polyurethane foam we use is environmentally safe and doesn’t degrade over time, ensuring a sustainable solution for your sidewalk repairs.

Ready to Fix Your Sidewalk? Contact FoamWorks Today!

If you’re dealing with uneven or sunken sidewalks, don’t wait for the problem to worsen. Raising sidewalks with foam is a fast, effective, and long-lasting solution that can save you time, money, and hassle. Contact FoamWorks today to learn more about how we can help raise your sidewalk with foam and restore the safety and beauty of your property.

Recent Comments