Is your parking lot in need of repair? Asphalt repair is a necessary part of maintaining a commercial parking lot. Here are 5 reasons why you should invest in asphalt repair:

1. Aesthetics- First impressions are important. You want your customers and clients to have a good first impression of your business.

2. Prevent further damage- By repairing cracks and potholes, you can prevent further deterioration of your parking lot pavement.

3. Safety- Cracks and potholes can be a safety hazard for both pedestrians and drivers. Parking lot asphalt repair will make your parking lot safer for everyone.

4. Enhance the lifespan of your pavement- Routine asphalt maintenance can enhance the lifespan of your pavement and save you money in the long run by prolonging the need for major repairs or replacement.

5 .Increase property value- A well-maintained parking lot will add to the curb appeal of your property and increase its value.

If you are considering investing in parking lot asphalt repair, contact us today for a free estimate!

Cracks and potholes in your parking lot can damage vehicles

Keeping a safe and well-maintained parking lot is critical for businesses of all sizes. Not only is it an important first impression for visitors or customers, but it can help protect their vehicles. Potholes and cracks in a parking lot can cause severe damage to tires and rims which can be costly to repair. It is essential that owners take proactive steps to have the surface of their parking lots leveled and maintained in order to create a safe environment for those who use it. Regular repairs such as filling potholes, patching cracks, power washing, and applying sealers should be carried out yearly or as needed if there are larger issues with the pavement surface in order to prevent any damage to vehicles.

Poorly maintained parking lots can give customers a bad impression of your business

Maintaining a clean and well-organized parking lot is essential to any business. By neglecting to keep up with the maintenance of your parking lot, you can send a negative message to customers as they enter and evaluate your establishment. A poorly maintained parking lot can reflect badly on an organization by conveying an attitude of apathy or indifference to presenting a professional image. Investing in regular maintenance tasks such as weeding, removing trash, restriping parking lines, and keeping pathways clear of debris will positively let customers know you are serious about the quality of your services or products. Properly maintaining your business’ parking lot is important for making the right first impression on customers – don’t ignore it!

Regular asphalt repair and maintenance can extend the life of your parking lot

Parking lot asphalt repair and maintenance is a crucial part of preventing costly damage to commercial properties. By scheduling regular repairs, you can protect your parking lot from further deterioration caused by weather, traffic and natural aging. Not only will proper repair help prevent dangerous potholes and cracks that can lead to liability claims, but it can also help extend the life of your parking lot significantly. A well-maintained parking lot looks professional and ensures safe walking surfaces while demonstrating a commitment to quality service that customers will see. Investing in Parking Lot Asphalt Repair now not only saves money on major repairs down the line, but also protects public safety, ensuring peace of mind for drivers, visitors and employees alike.

Asphalt repair is more cost-effective than replacing an entire parking lot

Asphalt repair can be a more cost-effective solution to maintaining a parking lot than choosing to completely replace it. Repair may be necessary due to the wear and tear of weather or heavy use, or even because of aesthetic reasons such as fading color. Asphalt repair is considerably less expensive because it puts the original surface back in shape without having to go through the process of removing large amounts of asphalt and re-paving an entire lot. Additionally, if properly maintained by attending regular maintenance, asphalt repairs can also extend the lifespan of a parking lot for several years. For these reasons, asphalt repair is a smart choice that helps save money and ensure that your parking lot remains visually appealing for an extended period of time.

You can avoid liability issues by keeping your parking lot in good condition

Regular maintenance of your parking lot is essential in avoiding liability issues. By implementing preventative measures such as regular inspections and repairs, you can ensure the safety of employees and customers while they enter and move through your property. Potholes, loose debris, and other hazards should be filled and fixed as soon as possible to make visitors feel secure when onsite. Additionally, it’s important to keep the lines clearly marked for parking spots to minimize confusion for drivers. When people have a safe experience navigating your parking lot space, you’re more likely to avoid any type of liability incident from occurring.

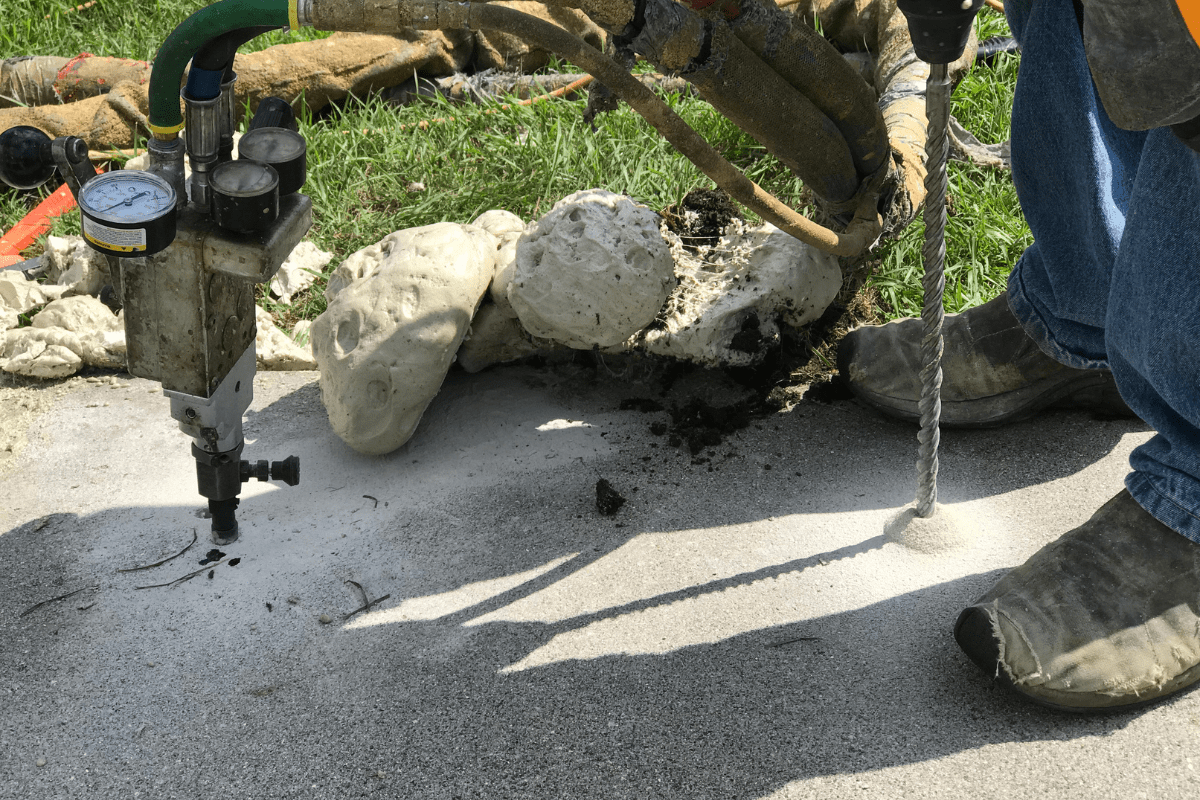

If you’re experiencing issues with cracks and potholes in your parking lot, it’s important to take action as soon as possible. Not only can these damages cause aesthetic problems for your business, but they can also lead to bigger and more expensive repairs down the road. At FoamWorks, we specialize in asphalt repair and maintenance – so we can help get your parking lot back into good condition quickly and affordably. Contact us today for a free estimate on our services!

Recent Comments