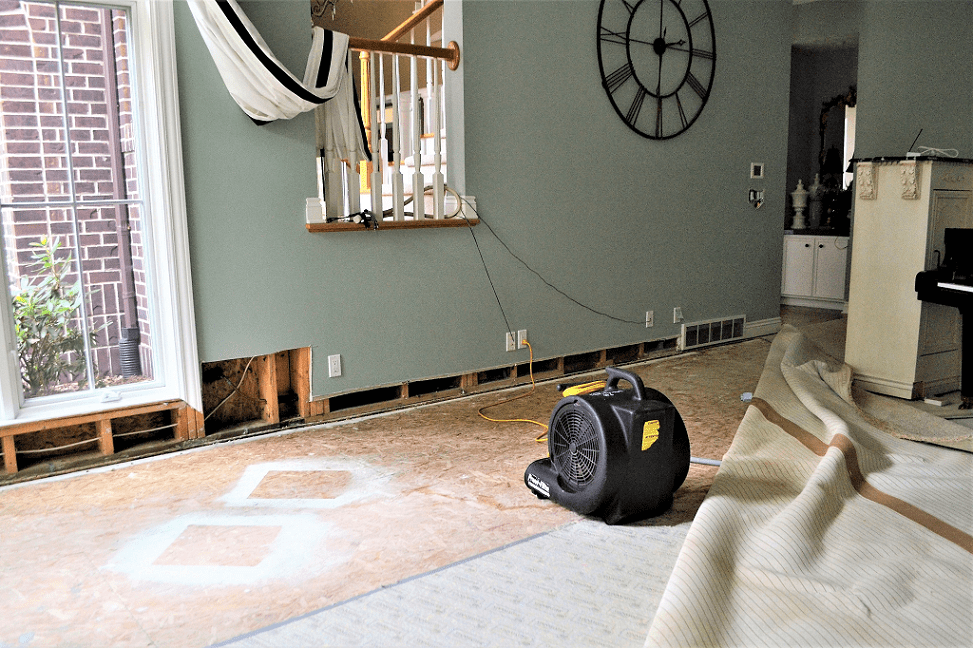

Lifting concrete with foam is a process that uses polyurethane foam to support concrete slabs and structures to the point where gravity can take over and the structure will hold on its own. The foam is a building material made from two chemicals that are mixed together, air, and water. Lifting concrete with foam is a more cost effective way of lifting concrete compared to using steel beams.

It costs less to lift concrete with foam than steel beams and other related methods. You can use the foam to support concrete slabs, piers, or other structures where you will be placing or building on top of them. You can also use the foam to stabilize a site as well as anchor building foundations into the ground properly.

Benefits to Lifting Concrete with Foam

1. Foam is Strong and Will Support a Lot of Weight

Foam will support up to 100 pounds per cubic foot, which is a lot more than the typical concrete that you are lifting. Foam can also support a larger area at one time compared to other similar methods. Foam is also very flexible and can be used to lift almost anything that you can think of.

2. It’s Chemical Free and Environmentally Friendly

The chemicals in foam are not harmful to the environment and it’s completely safe for humans as well as animals so there are no concerns when using foam in different projects or lifting concrete with foam around children or pets.

There is no worry of workers being poisoned, the foam will not absorb any toxins into the chemicals so there is no risk of that happening. Also the foam will not produce any greenhouse gasses like carbon dioxide or have a negative effect on the ozone layer.

3. Lower Cost than Steel Beams and Other Related Methods

More money comes out of your pocket when using steel beams because you have to purchase them and also provide labor as well as heavy machinery to lay them down into place. This can be a big expense and will cost you more than using foam.

Foam is comparatively inexpensive and can be bought in large quantities without breaking the bank, which allows you to use less of your money on the project. Foam is lightweight, which means it doesn’t take a lot of effort to put it into place.

4. Foam is Easy to Use and Will not Take Much Time to Install

All you have to do is spray or pour the foam onto the wood or concrete foundation for it to hold it down until it sets in place, then you can finish the construction project that we’re working on. You can also use the foam to stabilize a site as well as anchor building foundations into the ground properly.

5. It’s Fast and Easy to Install

The foam is very lightweight and can be installed by single people or a few people working together so you don’t have to wait for a specialized crew that is skilled in concrete work, steel work, welding, or other similar skills.

Once your foam is down it will stay without any more worry of it being taken back up by the wind or water currents so you don’t have to worry about it lifting off and causing damage to your building or structure. You can also leave the foam in place until you are ready to finish construction of the project.

Recent Comments