Is your concrete driveway, patio, or sidewalk looking a bit uneven these days? Uneven concrete is not only unsightly but can also pose a significant tripping hazard. The good news is that fixing it is easier than you might think! Whether you’re a DIY enthusiast or prefer to call in the pros, we’ll walk you through how to repair uneven concrete and get your surfaces back to looking their best.

What Causes Uneven Concrete?

Uneven concrete can happen for a variety of reasons, including:

- Soil Erosion: Water can wash away the soil underneath your concrete, causing it to sink.

- Poor Installation: If the concrete wasn’t laid properly in the first place, it might settle unevenly over time.

- Heavy Loads: Excessive weight from vehicles or heavy equipment can cause concrete slabs to sink or crack.

- Weather Conditions: Freeze-thaw cycles can lead to cracks and uneven surfaces.

Understanding the root cause can help you choose the best method to repair your uneven concrete.

DIY Methods to Repair Uneven Concrete

For those who love a good DIY project, here are a few methods you can try:

- Concrete Resurfacing:

- Clean the Surface: Start by thoroughly cleaning the concrete with a pressure washer to remove dirt and debris.

- Apply Bonding Agent: Use a concrete bonding agent to ensure the new layer adheres properly.

- Mix and Apply Resurfacer: Mix the concrete resurfacer according to the package instructions and apply it evenly with a trowel.

- Self-Leveling Compound:

- Prep the Area: Clean the surface and repair any major cracks.

- Mix the Compound: Follow the instructions to mix the self-leveling compound.

- Pour and Spread: Pour the compound onto the concrete and use a trowel or spreader to ensure it’s evenly distributed.

- Concrete Grinding:

- Rent a Grinder: You can rent a concrete grinder from most hardware stores.

- Grind the Surface: Use the grinder to smooth out the high spots on the concrete.

When to Call in the Professionals

While DIY methods can be effective for small areas, larger projects or severe damage might require professional help. Here’s where FoamWorks comes in! Our foam injection slab repair is a quick and cost-effective solution for fixing uneven concrete.

Why Choose Foam Injection Slab Repair?

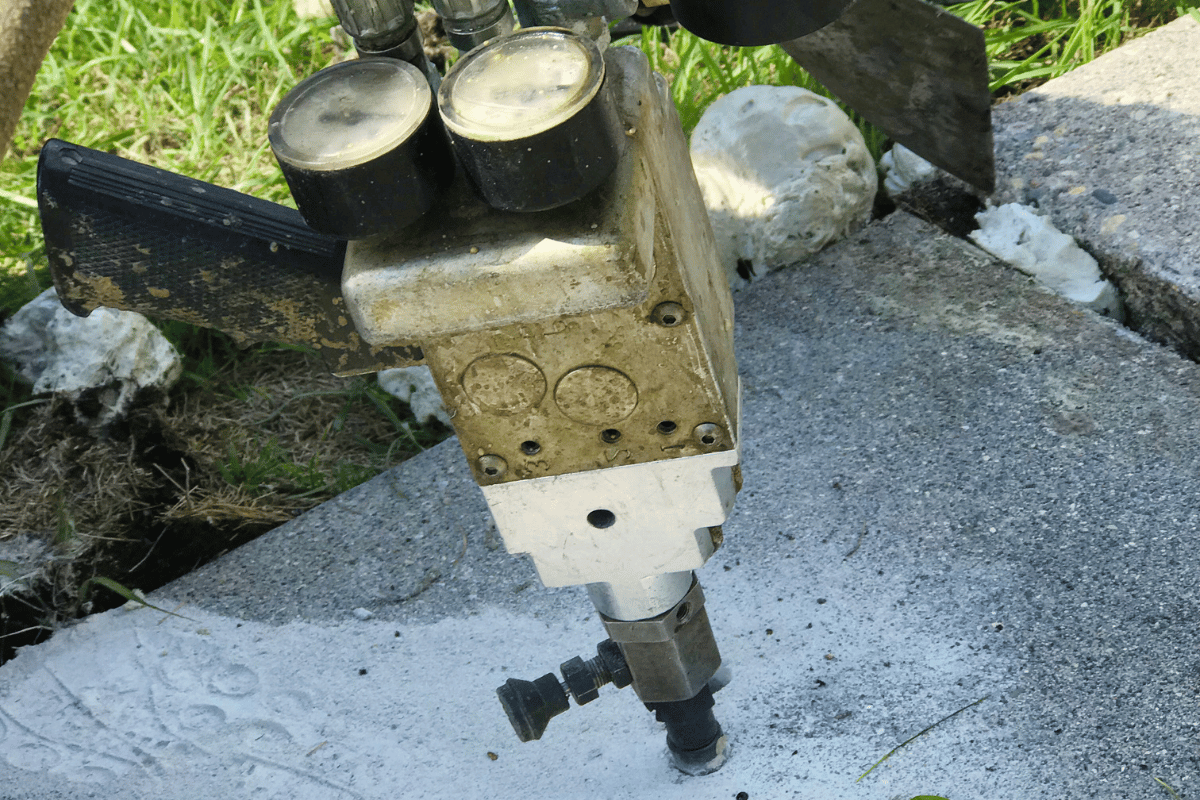

Foam injection slab repair involves injecting a high-density polyurethane foam under the concrete slab. As the foam expands, it lifts and levels the concrete. Here are some of the benefits:

- Quick and Efficient: Most jobs can be completed in a few hours.

- Cost-Effective: Cheaper than replacing the entire slab.

- Durable: The foam is resistant to moisture, chemicals, and pests.

- Minimal Disruption: No need for heavy machinery or extensive digging.

Step-by-Step Foam Injection Process

- Assessment: Our team will evaluate the extent of the unevenness and determine the best injection points.

- Drilling: Small holes are drilled into the affected area.

- Foam Injection: High-density foam is injected through the holes, expanding and lifting the concrete.

- Sealing: The holes are sealed, and the surface is smoothed out.

- Final Inspection: We ensure everything is level and stable.

Contact FoamWorks Today!

Ready to say goodbye to uneven concrete? Contact FoamWorks today for a free consultation and let our experts handle the job. Whether it’s your driveway, patio, or sidewalk, we’ve got you covered.

Repairing uneven concrete doesn’t have to be a headache. With the right approach and a little know-how, you can enjoy smooth, safe, and beautiful surfaces once again. Whether you choose to tackle it yourself or call in the pros, you’ll be glad you took the steps to fix those pesky concrete problems.

Recent Comments