Expert Bulkhead Repair in Dallas-Fort Worth

Bulkheads play a critical role in preventing soil erosion, stabilizing waterfront properties, and providing necessary structural support. However, over time, bulkheads can deteriorate due to soil erosion, water pressure, and environmental factors. If left untreated, this can lead to costly structural failures and property damage.

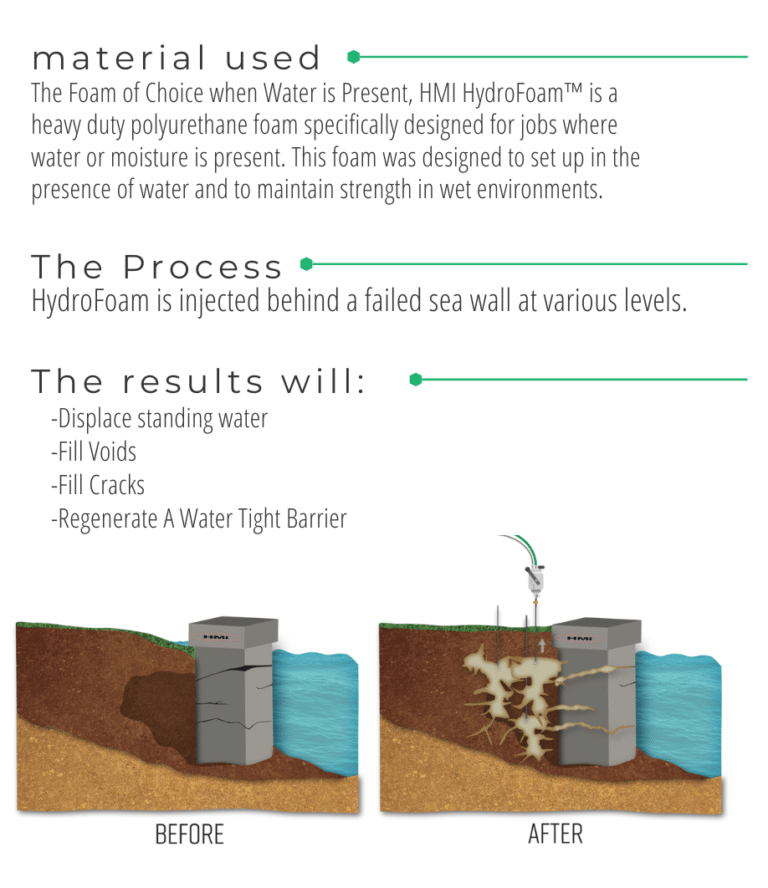

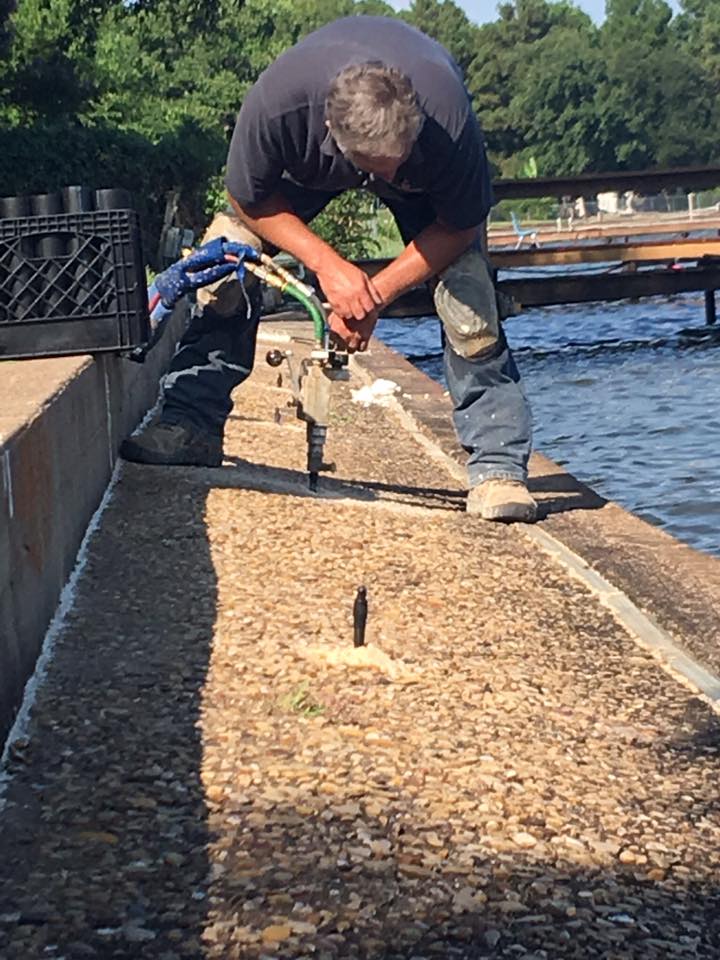

At Foamworks, we specialize in bulkhead repair in Dallas-Fort Worth, offering a cost-effective and long-lasting solution using polyurethane foam injection. Our advanced repair process restores stability by filling voids, strengthening the soil, and preventing further erosion.